Here I speak to Sally Strachey and Rachel Lawson from conservation contractors and expert stone conservators Sally Strachey Historic Conservation. I ask them about their experiences working with Reigate Stone, and they explain in detail the process they used at the Bell Tower, Tower of London, in 2015.

Sally, when did you first come across Reigate Stone and how much time does SSHC spend working with 'problem stones'?

Sally Strachey: I first came across Reigate in the second half of the 1980’s when the company I set up with five colleagues called Nimbus worked in London and the South East. SSHC works on a wide range of stones of all geological types, often considered problem stones. Another example is Lias. This is due to the fact we cover a wide area of operation. This includes sandstones as well as limestones and stones that often struggle to know which they are, like Reigate Stone!

I know you have done a lot of work on mortar design and specification, how much has changed since you started and what are the trends?

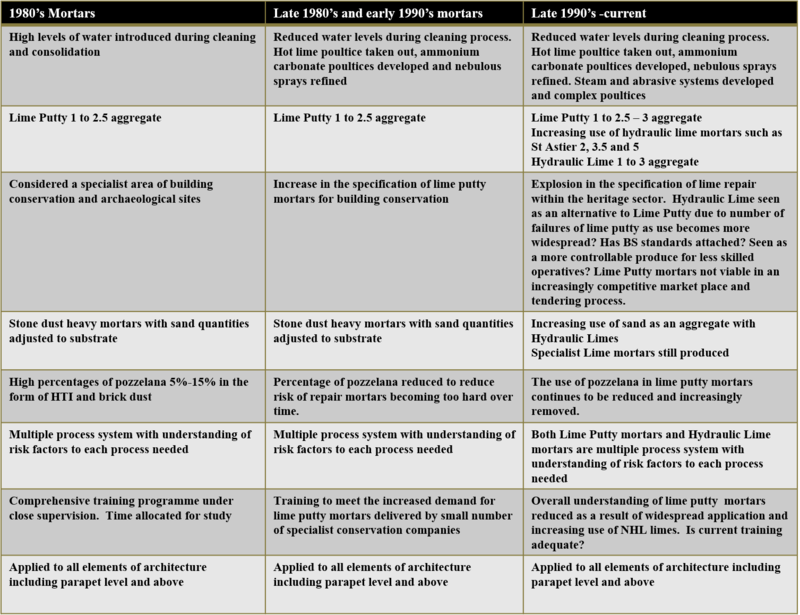

SS: This is a topic for itself, and I gave a lecture on it recently where I tried to capture the main changes (see table below). Looking forwards, climate change is demanding changes to the design of mortars and also the approaches we use. Challenges include more rapid biological soiling linked to increases in moisture and humidity. When we talk about lime putty or NHL, every material will have its uses and it drawbacks. In our work at Corfe Castle for example, NHL mortars loaded with stonedust performed well for the capping and high level pointing. So we have to keep an open mind and remember that we are working case by case.

Rachel, tell me about your background in historic buildings. How did you come to be a Conservator and SSHC?

Rachel Lawson: I’ve been involved in the conservation of historic buildings since the beginning of 2013. Following my BA in Art History, I was keen to use my degree in a more practical profession and I looked to conservation. During my MA in Conservation Studies, I realised that I was not particularly interested in working in a museum. My dream was to work on sculpture and architectural elements, so I looked for some on-site work experience and Cliveden Conservation offered me an internship. I found the work interesting, but I wasn’t prepared for the cold, hard and mucky conditions; it was certainly a shock to the system after the studio environment I had been used to!

So, after completing my studies I began looking for jobs in the management and museum side of conservation after all. But then I got another call from Cliveden asking if I would be interested in 5 weeks work restoring the crystal grotto at Painshill Park, Surrey. Five weeks turned into 5 months and I haven’t really looked back since. The work was so unique and interesting, and I even grew to enjoy the tough conditions. In 2014 I began working with SSHC who have been really supportive with my career progression and a pleasure to work for. In May 2015 I moved on to the Bell Tower and Queen’s House project at the Tower of London for 6 months.

That project involved conservation work to large areas of Reigate Stone masonry at the Bell Tower. How much emphasis was put on this within the whole project? What was your brief for the Reigate masonry?

RL: The project was large and comprised a variety of different areas, materials, and trades. In terms of volume and time Reigate Stone was a small part of the project. However, there was a lot of emphasis placed on its conservation; of all the elements we worked on it was definitely the most technical. The conservation of the stone was completed by me and one other conservator in order to ensure it was done carefully and according to the specifications. It was one of the last bits of work we did on the project, once the scaffold was down, as it was at the base of the Bell Tower.

There were two main types of stone: Ragstone and Reigate Stone. The Ragstone was cleaned and defrassed using superheated water jets and dry brushes to remove loose debris. In areas of Reigate masonry, this work was minimal due to the fragility and friability of the stone. It was important to preserve the Reigate stonework in its current state as much as possible so there was little to no defrassing and we only used soft brushes. Water jets weren’t used at all. Any failed, deteriorating or cementitious pointing mortar was removed and replaced with a suitable lime putty mortar. In order to avoid damage, hard pointing had to be carefully removed using an abrasive wheel to release the pressure rather than just with chisels. We used 110 volt 5” grinder to cut a release joint in the pointing, being careful to avoid the edges of the stone. The depth of the release joint depended on the undulation and condition of the surrounding stone, but was about 25 mm. A small sharp chisel was then used to remove the excess cement. This preserved the arisses as much as possible and did not cause them to crumble too much. As you know Reigate Stone is very fragile, so some loss was unavoidable during the de-pointing, but I believe the method we used was the most safe and effective. The cutting out of the cement pointing took about 2 days. We then did the repointing, mortar repairs, and treatment over about 3-4 weeks. We pointed the Reigate stone flush which gives the most protection to the friable stone and should prevent excess weathering. Generally, flush pointing is a more durable type of pointing and this is particularly important with friable stone. To consolidate the stone, we then sprayed on several coats of waterborne HCT (Hydroxylating Conversion Treatment).

That built directly on the HCT trials from 2001, when Norman Weiss and his team applied it to a small area of the Bell Tower. Recent surveys suggest some of the stone treated in 2015 hasn’t been as well consolidated as that treated in the trial period. There are all sorts of possible reasons, from differences in the calcite content of the Reigate, to the additional use of a non-water-based silane in some of the trial areas. I found some documents dating back to the early 90s, which show that after work on the internal Bell Tower masonry, use of waterborne treatment (in that case limewater) was not advised because of concerns over high water uptake. It’s such an unusual stone and there is so little clear guidance. What resources or expertise did you draw upon?

RL: Having never worked with Reigate before we relied heavily on expertise and instruction from Ian Angus. With regards to the decision of what pointing to remove for example, this was very much done in conference with Ian. We would identify the worst areas and Ian would specify further areas to remove if necessary. Beyond the condition of the mortar, there was a need to strike a balance between only removing the worst pointing and aesthetically creating a uniform look, to avoid small islands of new pointing. Discussions with Ian took place at least every couple of weeks during inspections, more frequently if necessary. Norman visited on at least one occasion as well.

SS: With regards to the point about lime watering, this was in general not widely used on friable stone past the late 1980’s due to the concern of mobilising soluble salts. We see now when reviewing the performance of early repair mortars, for example on the sculptures at the West Front of Wells Cathedral, which were treated in 1980, that the levels of water applied during the cleaning and consolidation process had an impact on the surface mortars. They became subjected to raised levels of soluble salts. So these problems recognised in Reigate Stone fit a general pattern.

RL: Yes, and I did also draw on the knowledge and experience I had conserving other stone that was particularly friable or liable to delaminate, or even historic plasterwork that was deteriorating. One of the things that motivates me in this field is the opportunity to work with new challenges and new materials, and to learn new skills. Reigate Stone was a great example of that. In stone conservation, a lot of the techniques we use now are the same as those used centuries ago, such as lime pointing. However, new techniques and materials are always being developed and these can sometimes be more effective than historic methods. I find the role of a conservator by its very nature balances practical, traditional skills with the more academic and scientific. This is even more true in the historic building industry. So, it is important to stay up to date with the latest materials, techniques and changing methods. I try to read conservation journals and articles where I can, although the material on stone conservation is often older than other disciplines.

Up until now I haven’t really had a chance to share my knowledge of working with Reigate Stone on this project, and I haven’t come across it in other projects. I have taken an interest in it though. It has such a distinctive and – in a way – beautiful deterioration pattern. It is definitely a stone I am keen to learn more about and gain more experience with.